Project Description

APS have just designed and built some new panels that are to be used in a ventilation system. The Workplace (Health, Safety and Welfare) Regulations 1992 require that employers provide effective and suitable ventilation in every enclosed workplace. This includes kitchens, which need ventilation to create a safe and comfortable working environment. Catering and cooking can produce significant amounts of fumes and vapours, as well as large amounts of heat.

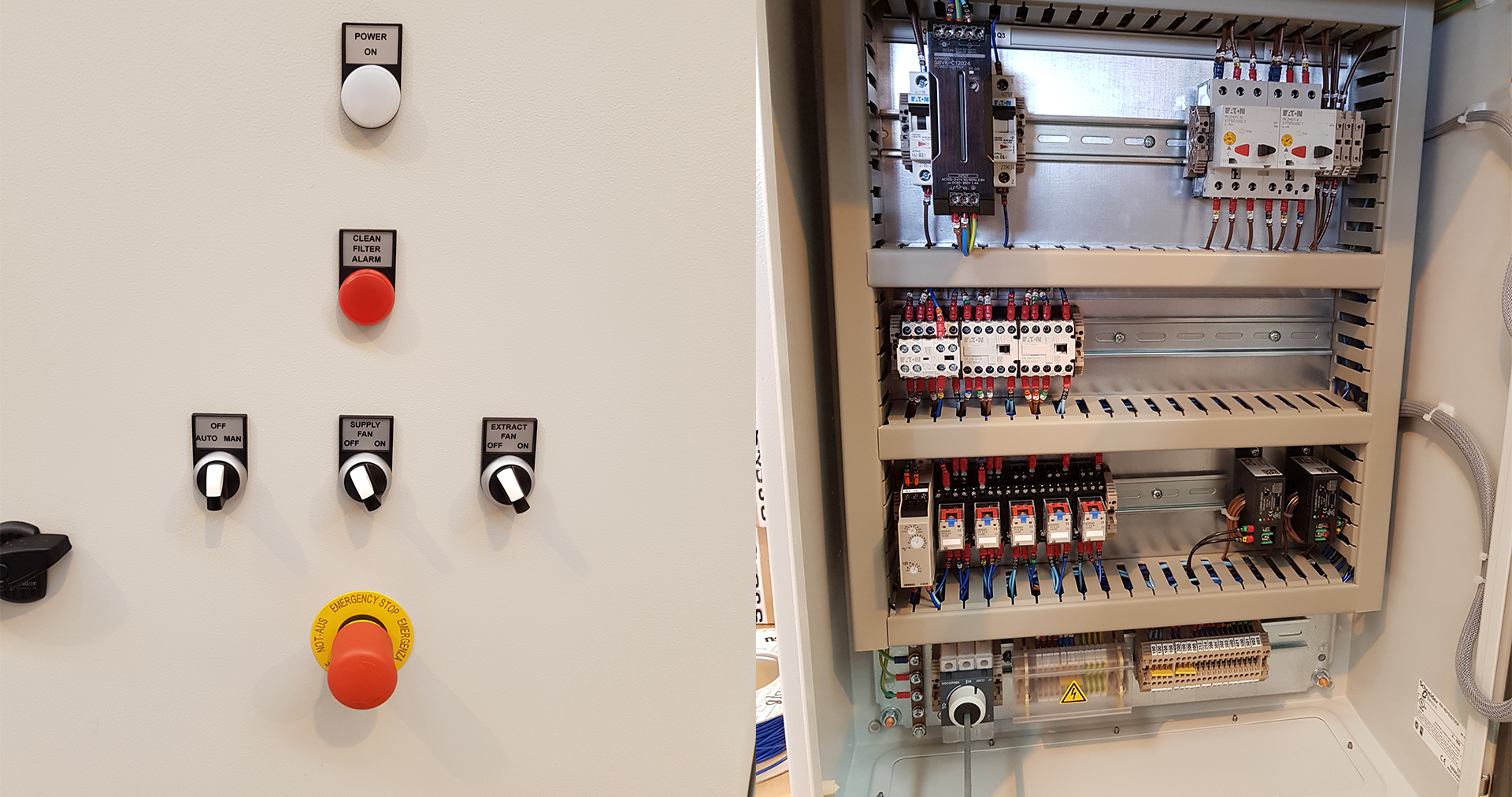

The ventilation system design should take into account the need to replace extracted air. Mechanical and/or natural means can provide make-up air, but it should be fresh and unadulterated from the outside. To do this the shown system controlled a supply and an extract fan and interacted with the gas control unit. The load of the fans are measured using a current switch which set a fixed load and closes 2 contacts when the load is above a minimal level.

Other factors including:

- Duct temperature

- Water temperature

- Frost detection

- Filter blockage

Are taken into account during automatic operation. When switching off the supply fan automatically stays on for a given time after the extract fan has stopped. Manual operation overrides these controls allowing the operator to switch the fans on independently. A filter blockage light tells the operator that the filters need replacing.

One possible energy saving measure is to replace the Direct on Line method of operating the fans with inverters. The initial cost is higher but very often standard installations are not exactly matched to the volume of air required and by slowing the fans down the energy used can be cut dramatically. If you can reduce the speed of the fans by 25% the energy used is half that at full speed due to the energy used in a fan obeys an inverse square law in relation to its speed.

Leave A Comment