Printing Industry

APS (Automation Products and Systems) have provided systems to the Printing Industry many times over the years.

To be able to design and supply control systems to the printing industry it is essential that we understand the needs of this industry in order to provide the best possible solution for any particular printing application. For example, it would be fairly easy to guess that the speed of production is important whilst maintaining accuracy of print but what may not be so obvious is that the customers of the printing machine manufacturer are demanding other things as well such as flexibility to meet trends in consumer spending, to change from one print run to another quickly and to be able to minimise waste on materials which can be very expensive.

To this end we have been able to use servo motor and servo drive technology with a PLC master and a touch screen with visualisation to achieve results such as gap saving, print recognition, print registration and improved duty cycle times.

Foil printing:

Foil printing:

There are a number of methods of foil printing including cold and cast and cure (Ultra Violet) methods.

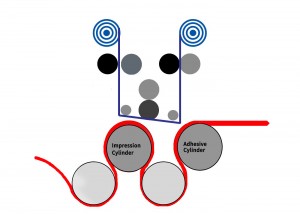

The following is a general representation of the process:

The control required of the foil depends upon the required printing effect. In some applications it is sufficient to simply match the linear speed of the foil to the substrate. This is done via an encoder which monitors the line speed and allows the nip drives to match this. The unwind speed will be determined by the diameter of the material left on the core. As the diameter gets smaller the diameter speed must increase to keep the linear speed the same. Tension control of the material is also an important factor to keep control of the web. This is achieved by taking the following into account.

· Calculating tension. The bigger the diameter the more torque is required from the motor to simply turn it round as its mass is greater. This must run at a slightly slower speed than the nip drive in front of it. Any extra torque (ignoring losses) manifests itself as tension in the material.

· Calculating speed: Load cells provide accurate measurements of the material tension. A simple P.I.D. algorithm can maintain the correct speed to keep the tension of the material as is desired.

Both tension and speed are calculated by a Lenze 8400 Top line drive

Leave A Comment