Build & Assemble

Naturally once a system is designed it needs to be built. APS conform to all the relevant European

standards. We train our engineers to build systems in an exact way. Two identical panels built by two

different engineers will look identical. This gives customers assurance on the consistency of supply.

Testing is also an important stage of the build. This is done by at least one person who has not built

the panel. This provides another level of fault detection in the final build.

APS will build panels to the customers design if this is required. This allows the customer to

concentrate on the core principles of the machine in question. The panel becomes a commodity that

the customer need not worry about. The panel will be delivered on time every time.

Not all of our services are at the high end of the engineering scale. Some of our customers require

simple cabling looms being made up with a specified connector wired to it. Others require the supply

of a drive, for example, pre-programmed. APS have supplied tens of thousands of such assemblies

with 100% customer satisfaction.

OUR BUILD & ASSEMBLE PROCESS

Once a customer has approached us with a particular build or assembly requirement the design

process is assessed. If engineering drawings are already assembled APS will produce a sample of the

required product for assessment by the customer. Once this has been approved APS will invest in this

process by designing and building any test equipment that is deemed necessary to assist in the quality

of supply. This is very rarely a high cost process and will usually involve some sort of switching

assembly with signal lights to confirm the functionality of the build.

BUILD CASE STUDIES

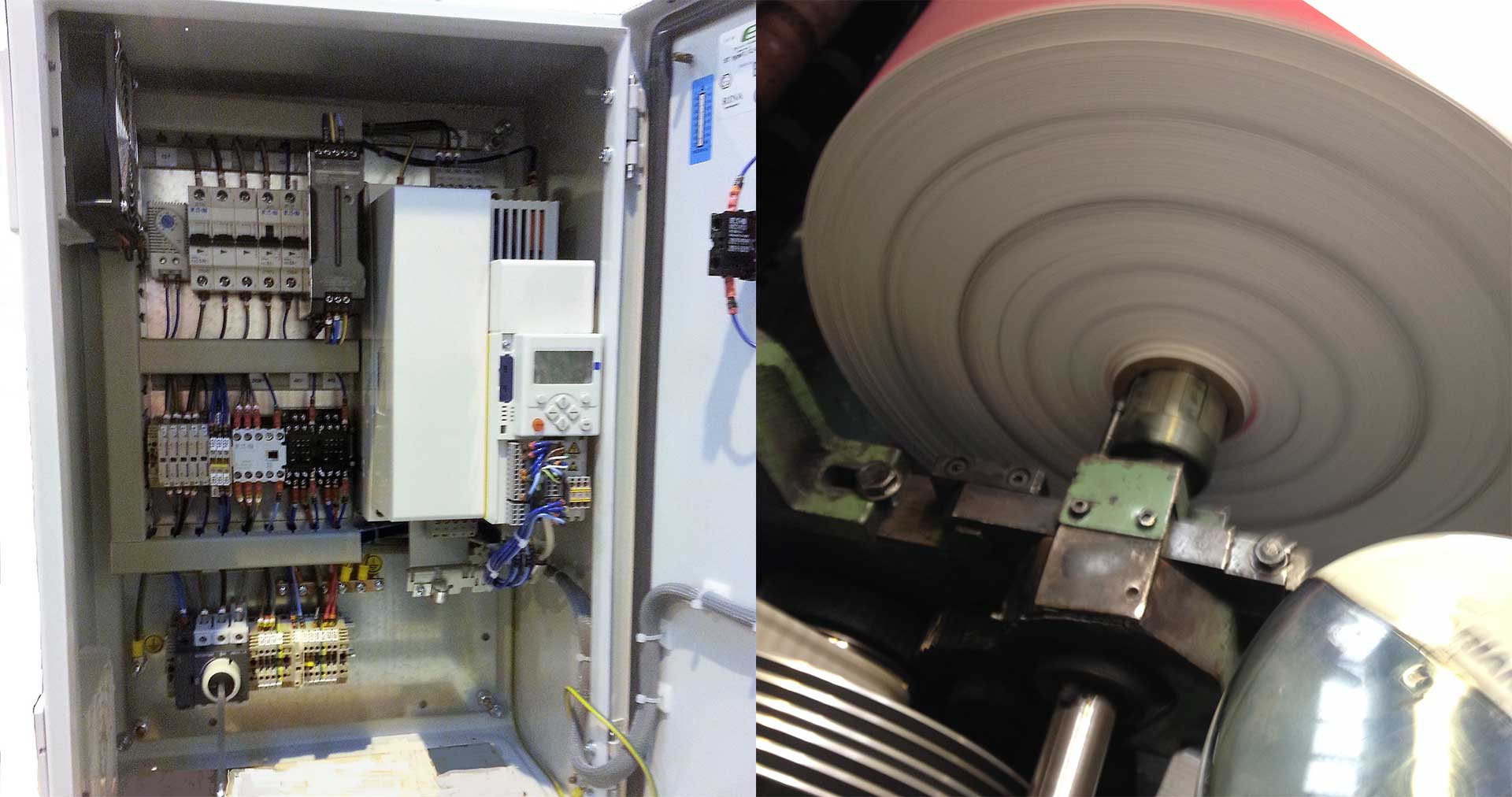

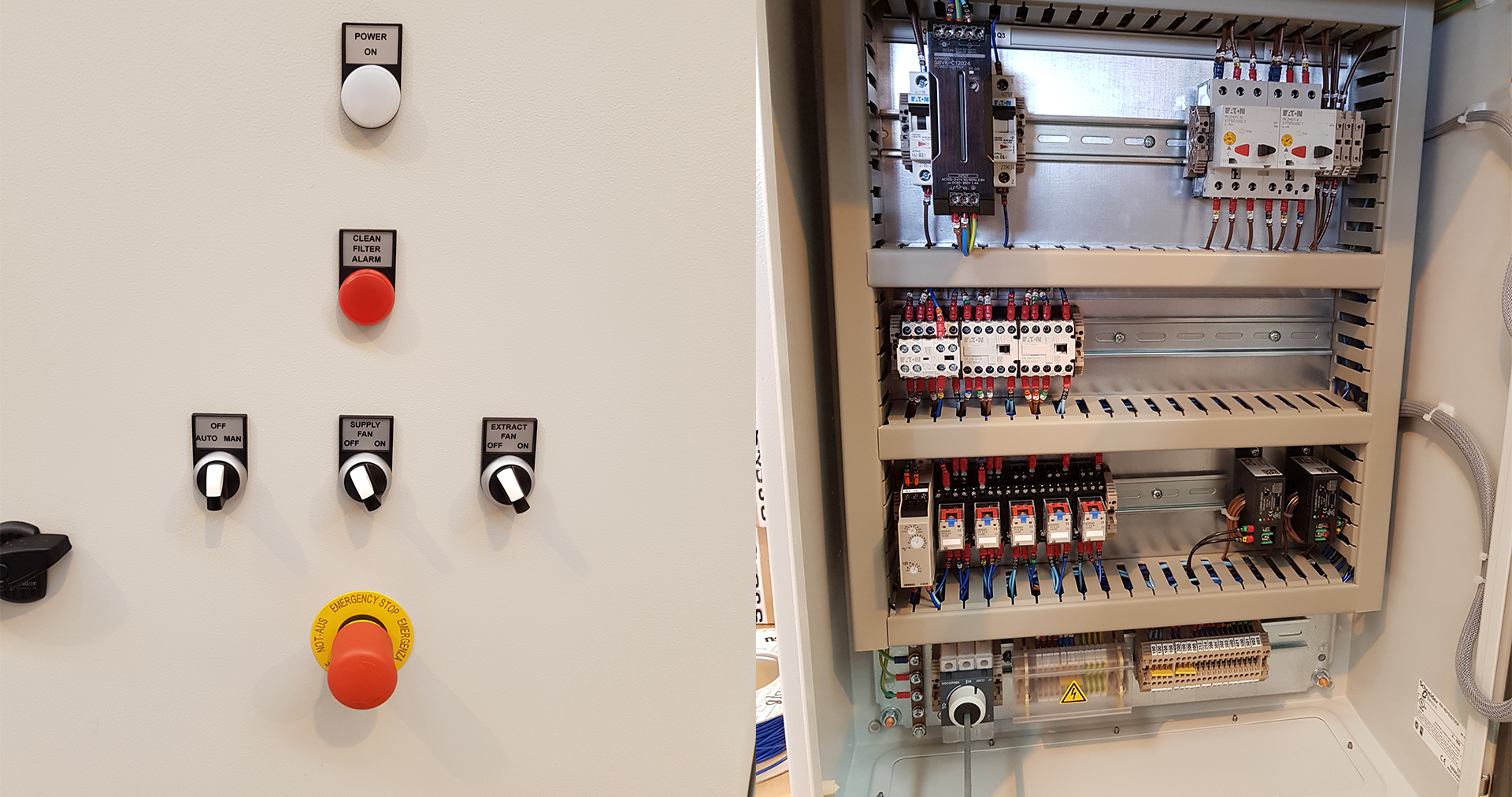

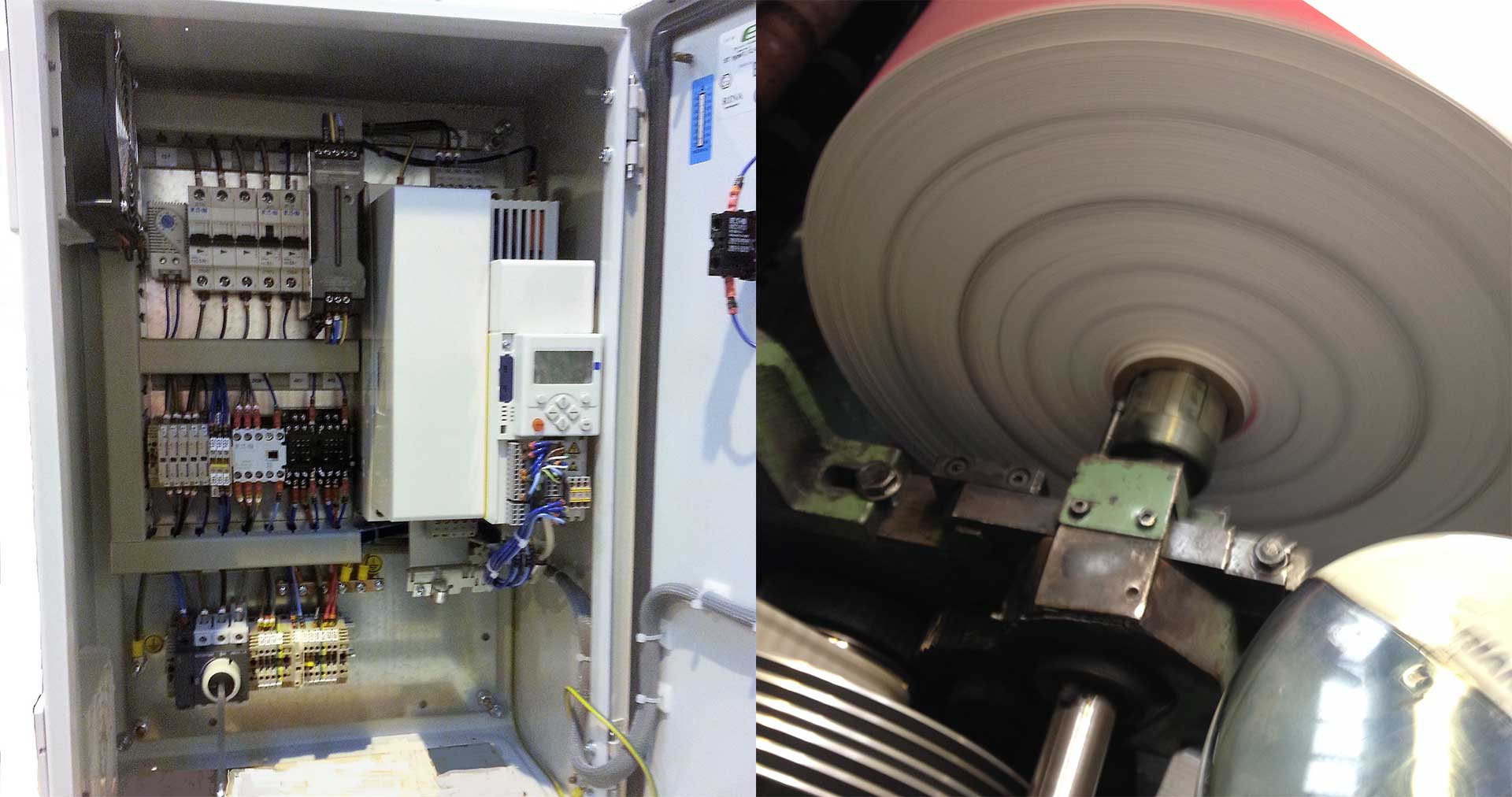

August 2018

Ventilation System

Project Description APS have just designed and built some new [...]

April 2018

Winding Control

Project Description David Emmett, the owner of British Paper Coils [...]

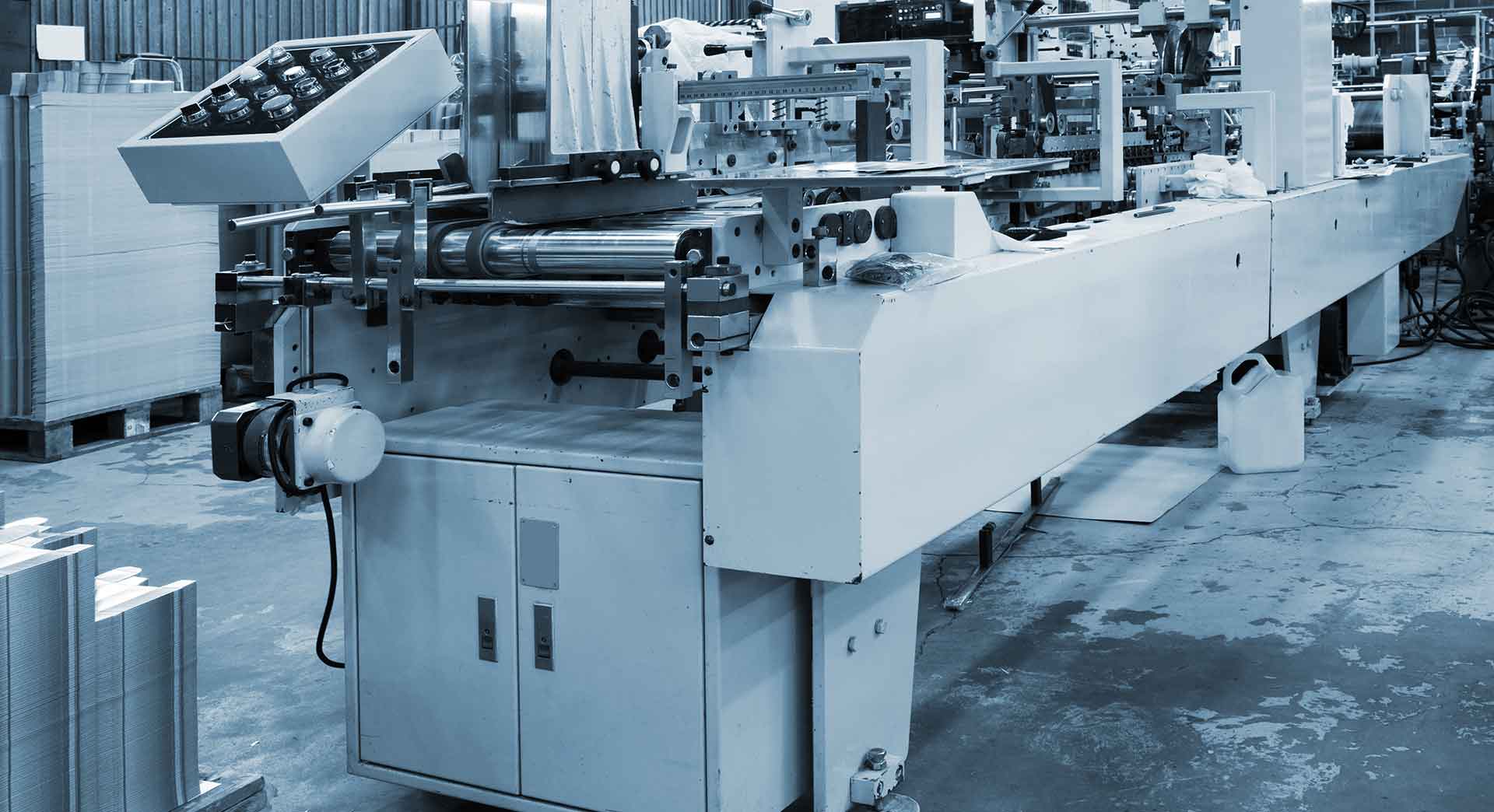

PRINTING INDUSTRY

Printing Industry APS (Automation Products and Systems) have provided systems [...]

If you are looking for an experienced product automation specialist or help with installtion, service or support then please fill in your details below and we will get right back to you.

If you are looking for an experienced product automation specialist or help with installtion, service or support then please fill in your details below and we will get right back to you.