Basic principles of hazard analysis

Identify hazard

Assess hazard

Reduce hazard to a tolerable level

Eliminate hazard entirely

Specify technical and organisational measures

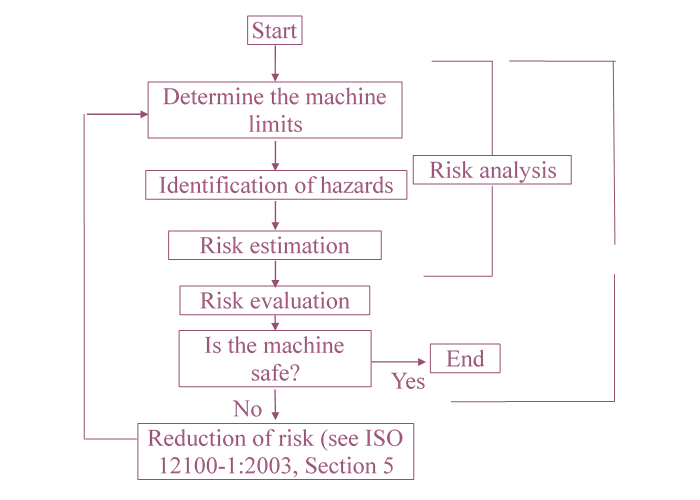

Procedure for hazard analysis

Approach of a hazard analysis Determination of machine limits

Application limits

o Operation modes

o Knowledge and competence of operator / different operators

Regional limits

o Area for machine motion

o Required space of operator

o Interface human / machine

Temporary limits

o Lifetime of machine or components

o Service intervals

Other limits

o Temperature, humidity, …

Approach of a hazard analysis Identification of hazards (1/4)

All necessary actions / contacts of persons in every operating mode / every process step, at every hazard area and in every phase of life must be considered.

Phases of life are e.g.:

o Transport, assembly, installation

o Commissioning

o Application

o Shutdown, disassembly, disposal

Approach of a hazard analysis Identification of hazards (2/4)

Operating modes / process steps are e.g.:

o Rigging

o Testing

o Teaching

o Change over

o Start

o Shut down of the machine

o Shut down of the machine in hazardous situation

o Debugging and –elimination

o Cleaning

o Automatic operation

o Off

Approach of a hazard analysis Identification of hazards (3/4)

Types of hazards

Mechanical hazards are e.g.:

Crushing, cropping, cutting or abscission, capturing or winding, feeding or trapping, shock, puncture or penetration, rubbing or abrasion, spurt out of liquids, beating of broken tubes

Other hazards are e.g.:

o electrical hazards

o thermal hazards

o noise, vibration, radiation, hazardous substances, …

Approach of a hazard analysis Identification of hazards (4/4)

Hazard areas

o Feed in

o Processing

o Feed out

o Changeover to other parts of the machine

Approach of a hazard analysis Risk estimation (1/2)

Determination of risk elements

o Measure of damages (slightly, seriously, deadly, number of persons) and

o Probability of damage

- Exposure to hazard (necessity of entry to hazard area, type of entry, duration, number of persons, frequency)

- Occurrence of event (reliability and statistical data, accident history, damage to health, risk comparisons)

- Possibilities to prevent or limit damage (training, duration of hazard until damage occurs, user informations, danger signals, display units, human capabilities)

Approach of a hazard analysis Risk estimation (2/2)

o Aspects which must be considered

o category of persons

o type, frequency and duration of exposure to hazard

o relationship between exposure and effect to hazard

o human factors

o efficiency of safety measures

o possibilities to switch off or bypass safety measures

o capability to maintain safety measures

o user information

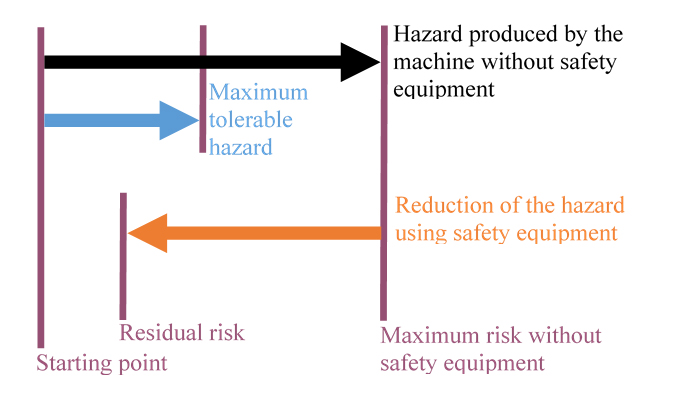

Approach of a hazard analysis Reduction of risk

o Priority of risk reducing measures:

o constructional measures

o barriers

- safety measures

o light barriers

- user information

o organisational measures

o trainings

CASE STUDIES

August 2018

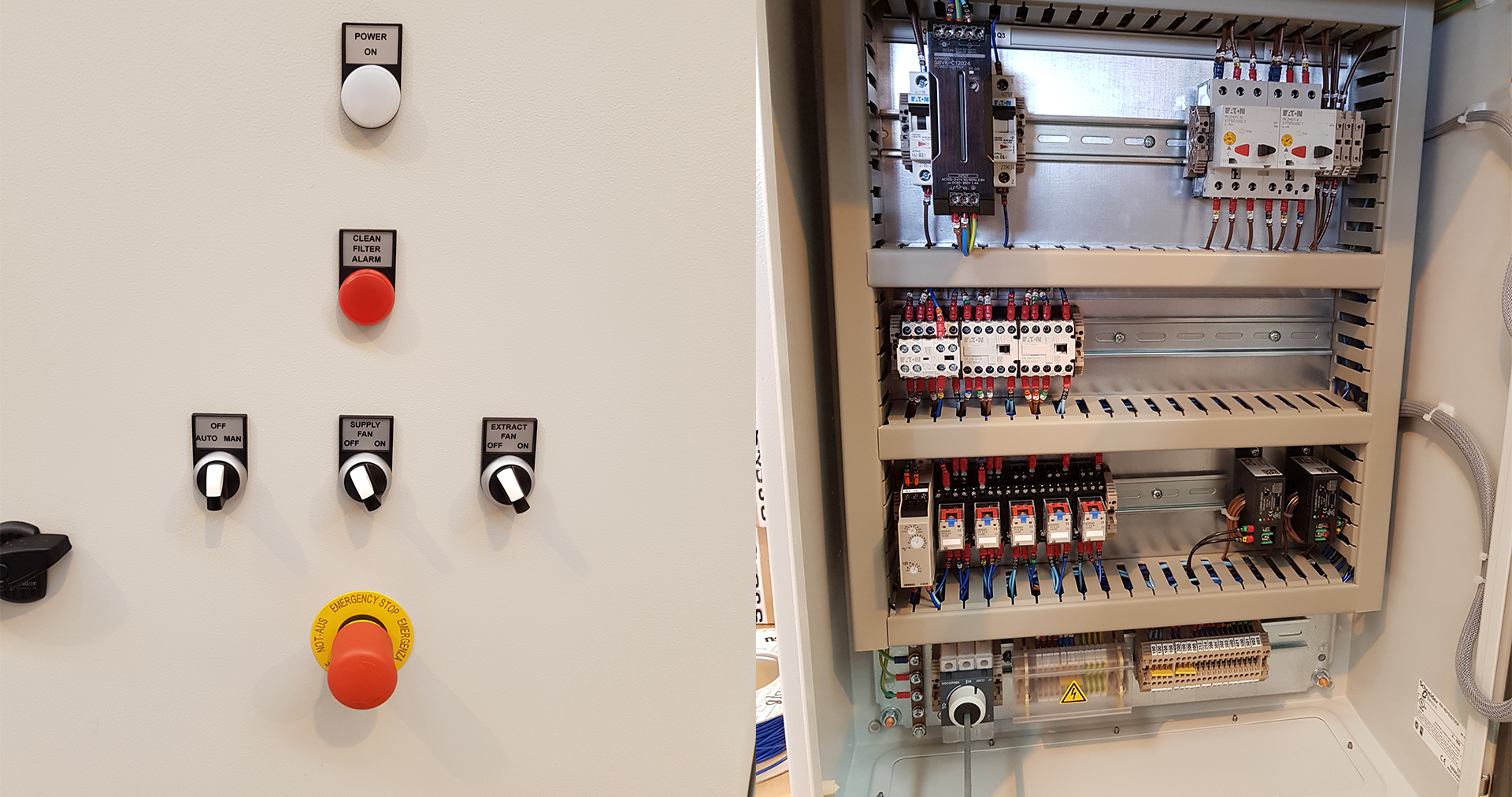

Ventilation System

Project Description APS have just designed and built some new [...]

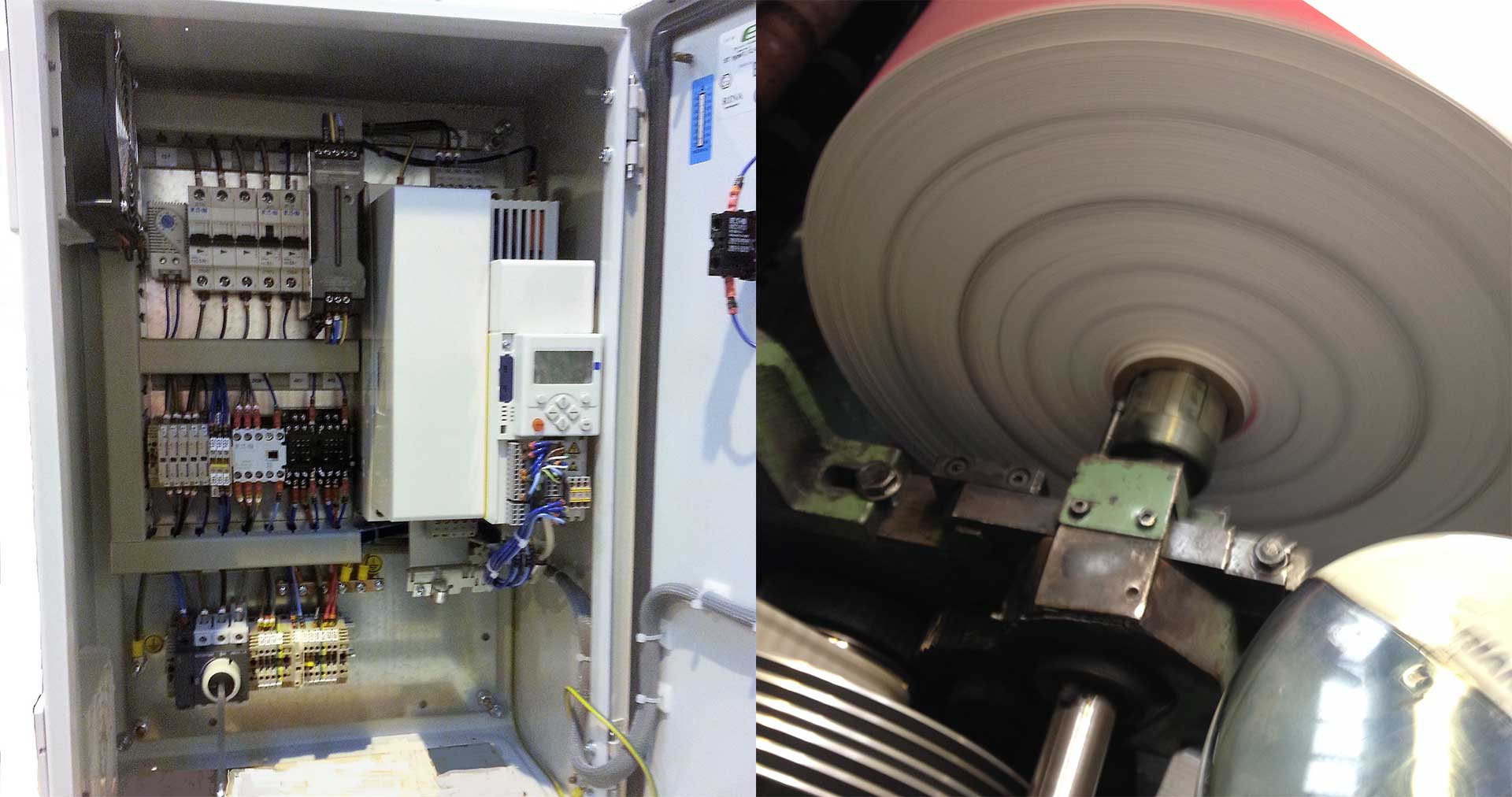

April 2018

Winding Control

Project Description David Emmett, the owner of British Paper Coils [...]

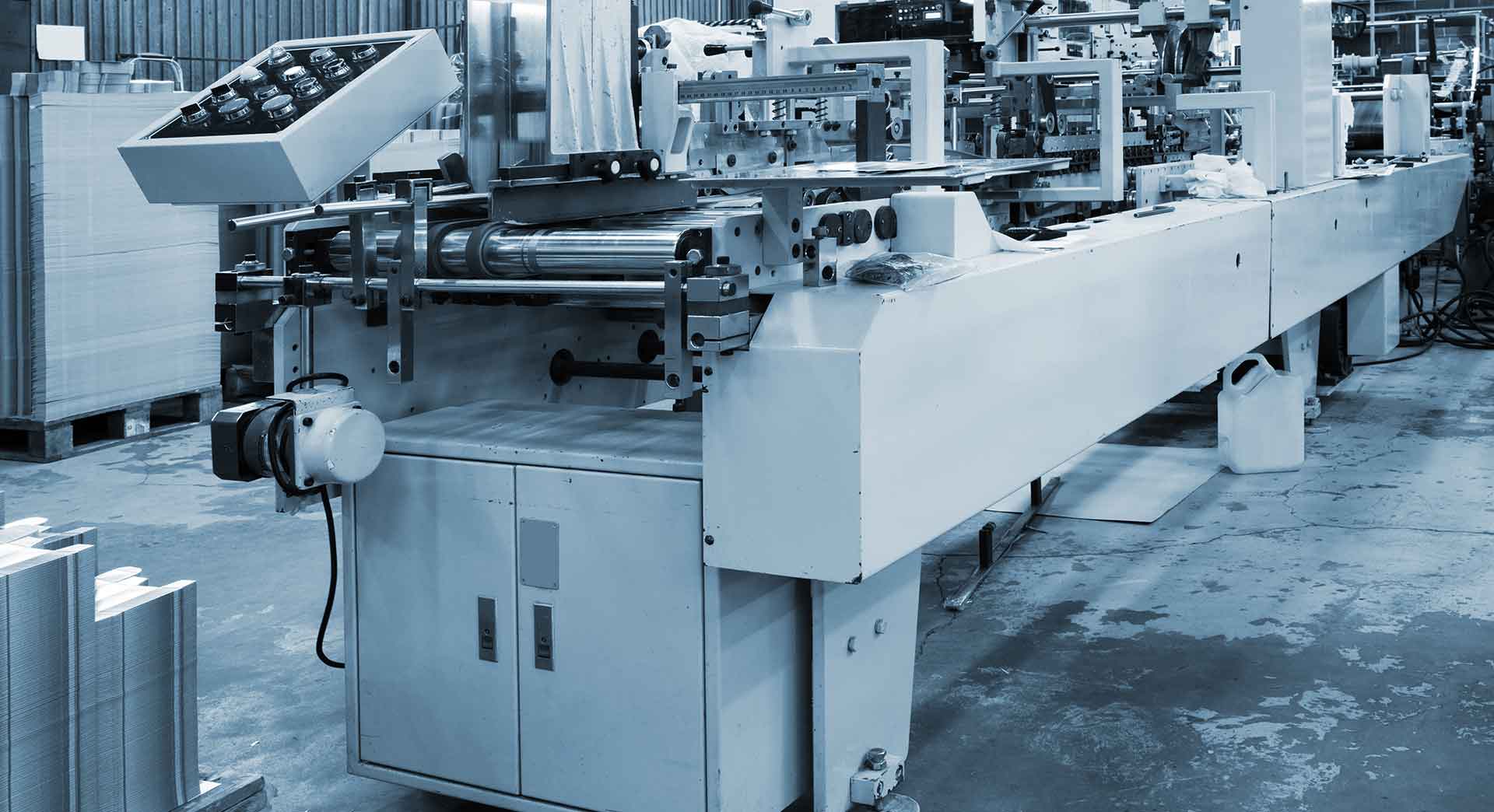

PRINTING INDUSTRY

Printing Industry APS (Automation Products and Systems) have provided systems [...]

If you are looking for an experienced product automation specialist or help with installtion, service or support then please fill in your details below and we will get right back to you.

If you are looking for an experienced product automation specialist or help with installtion, service or support then please fill in your details below and we will get right back to you.