ABOUT US

Automation Products and Systems Ltd were formed in 2010. Based in the North West of England we are about 5 miles away from the M6/ M62 junction.

20 YEARS EXPERIENCE

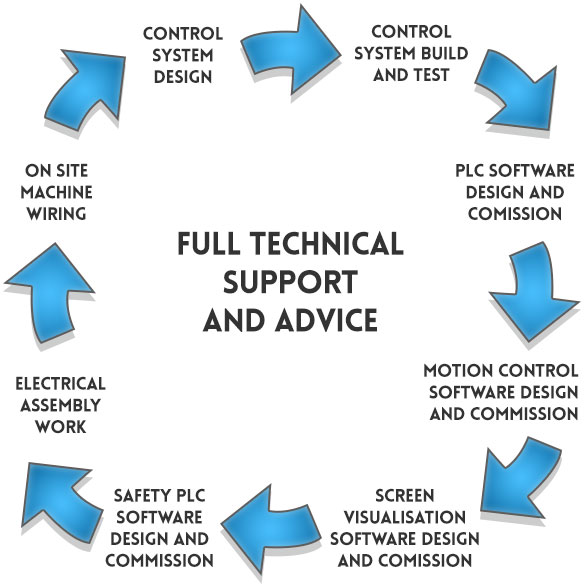

Automation Products and Systems Ltd can offer the following services

Using the correct control system architecture is a vital part of producing a machine which can achieve the desired performance whilst coming in on budget. Choose the wrong components and the engineering time can be stretched causing costly delays in delivery and development costs. Choose hardware that has much more functionality than the machine requires and this can also add to build costs. At APS Ltd we have a depth of experience to ensure that that the correct choices are made early enough in the design to ensure an excellent solution.

After consultation with the customer a detailed quote is provided which encompasses the specification that has been laid down. Using Autocad Electrical a design is developed which is provided for approval by the customer. Once the design is fully approved the design goes onto the manufacturing stage.

We emphasise the need for quality, accuracy and aesthetics in our panel and component build. Our panels are judged on the following

- Do they meet current legislation and safety standards?

- Do they work to the functionality determined in the specification and design?

- Does the panel look professional?

Our engineers are trained to fulfil all the criteria you require in a panel. We use vigorous and complete testing procedures to determine any non-conformance to the design and test documentation is produced and available to the customer. All jobs are photographed in great detail to ensure a good record of what has been produced.

The same criteria applies to the PLC design as to the hardware. Choices made at the early stage of the project can be crucial to the efficient flow of the project. This aspect requires a much deeper understanding of the machine process than the hardware design. Once the concepts have been fully formed as much software is done at our premises as possible. The PLC controls the process of the machine and needs to communicate with other hardware which may have other functions such as a screen.

If you have any such requirement please contact us to discuss further.

OUR GUARANTEE

We were fortunate enough to start with a strong customer base and it did not take long for us to establish ourselves as a serious company in the field of control and automation. Our customers have high standards and we know from experience that the control system is a fundamental feature of any machine. After all, this is where the operator works and so the quality and aesthetics of the control system can finish the look of the machine in a professional way.

However, this is not the whole story. There is also the issue of machine safety, of which the control system design is fundamental, and also the conformity to standards as laid down by the European Union. Automation Products and Systems Ltd take these issues seriously and are able to produce a certificate of conformity for every system it designs and builds. Safety is a very complicated issue (see our comprehensive guide) and many customers find the standards a bit of a minefield which they are tip toeing their way through. Automation Products and Systems Ltd can help in this matter as we have a lot of experience in this field.

However, this is not the whole story. There is also the issue of machine safety, of which the control system design is fundamental, and also the conformity to standards as laid down by the European Union. Automation Products and Systems Ltd take these issues seriously and are able to produce a certificate of conformity for every system it designs and builds. Safety is a very complicated issue (see our comprehensive guide) and many customers find the standards a bit of a minefield which they are tip toeing their way through. Automation Products and Systems Ltd can help in this matter as we have a lot of experience in this field.

Building and designing control systems would be of little benefit if the customer does not have the software experience to make the system work. Automation Products and Systems Ltd are happy to be able to offer a complete service which include PLC software, Motion control software, Visualisation software and drive parameter set up.

We are also flexible in what we can offer. Some of our customers ask us to assemble special cables and connectors with the result that we have shipped many thousands of components and can to date claim to have zero returns for this service. The reason for this is that we invested and built a special test system and we use this to test the product three times during the assembly. The last of these tests are while the packaging is already applied. This gives us the confidence that the assembly is secure.

Automation Products and Systems Ltd are a growing company because our focus and priority is our customer. If you have an enquiry about anything that you think we might be able to help you with, please don’t hesitate to contact us via our contact page.

Our software engineers are experienced in all leading software packages:

Design: Auto Cad Electrical

PLC: Codesys PLC Designer

Visualisation: Visiwin

Safety PLC: Safe PLC2

Drives: Engineer/Easy Starter

If you are looking for an experienced product automation specialist or help with installtion, service or support then please fill in your details below and we will get right back to you.

If you are looking for an experienced product automation specialist or help with installtion, service or support then please fill in your details below and we will get right back to you.